The aim of this invention is to control the corrosion of steel objects and to prevent the formation of crusts in cooling systems or boilers using some seaweed and non-polluting marine algae extracts rather than chemicals, and thus to be used in food and pharmaceutical industries. It also aims to reduce pollution on the watercourse and thus reduce the cost of water treatment in water companies.

The most important advantages of the invention are that they are inexpensive and safe for the environment. They are made up of natural materials that are available and uncomplicated to manufacture and play the same role as chemicals imported from abroad, which will save money, plant factories and employ young people. It is also important to reduce the use of chemicals used in water treatment (chlorine and Alum) and thus reduce the cost of money spent in the treatment of water. Thus saving the wasted money in importing chemicals that harm the environment and chemicals used in the treatment of water and thus increase the national income.

In order to promote the product, there must be a company that produces and markets different factories and companies, and follow up with them in order to help them to control the corrosion rates to achieve the highest degree of efficiency.

This is called the science of metal erosion and protection, and is the work of many scientists and researchers, to control it, because metals, whatever the iron rust, and corrosion varies depending on the type of metal and the center in it.

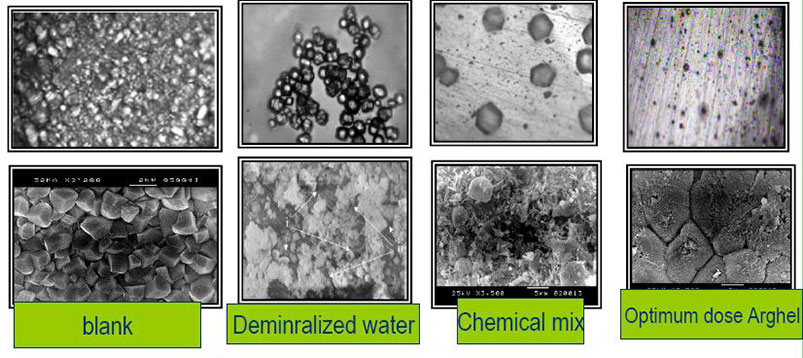

In many industries, water is widely used in the process of heat exchange to remove unwanted heat in some industrial operating systems. The warm water from the cooling process contains soluble salts, organic matter and microorganisms that lead to metals corrosion. , And crusts are deposited in the "pipes" of the cooling systems, resulting in partial or total blockage.

The more developed countries are able to control corrosion rates, stressing that corrosion can not be stopped but controlled. Instead of changing the pipe every 10 years, using corrosion control materials can be changed every 50 years